Often with the discovery of Mercury, time is critical.

Mercury in production streams can impact facility integrity, product quality, environmental discharges and introduce hazards during equipment inspection and maintenance.

Exceeding product quality specifications will ultimately cause an extended plant shutdown until a mitigation plan can be implemented.

Technical Director

"We bring unique insights from both the client and contractor side to deliver wholistic solutions to complex and technically challenging problems."

We quickly assess the extent of the problem, identify all the options and bring clarity to the decision making process.

Treatment of the product streams is often the starting point in the options identification process, and in taking this approach product quality can generally be assured. Plant integrity, air emissions and water discharges are just a few considerations that may be overlooked, not to mention it could be the highest cost option if we were to stop there.

The solution selected is the generally the one that best mitigates the risks to personnel, product specification, plant integrity and emissions to ALARP, uses proven technology, is practical to implement and is cost effective.

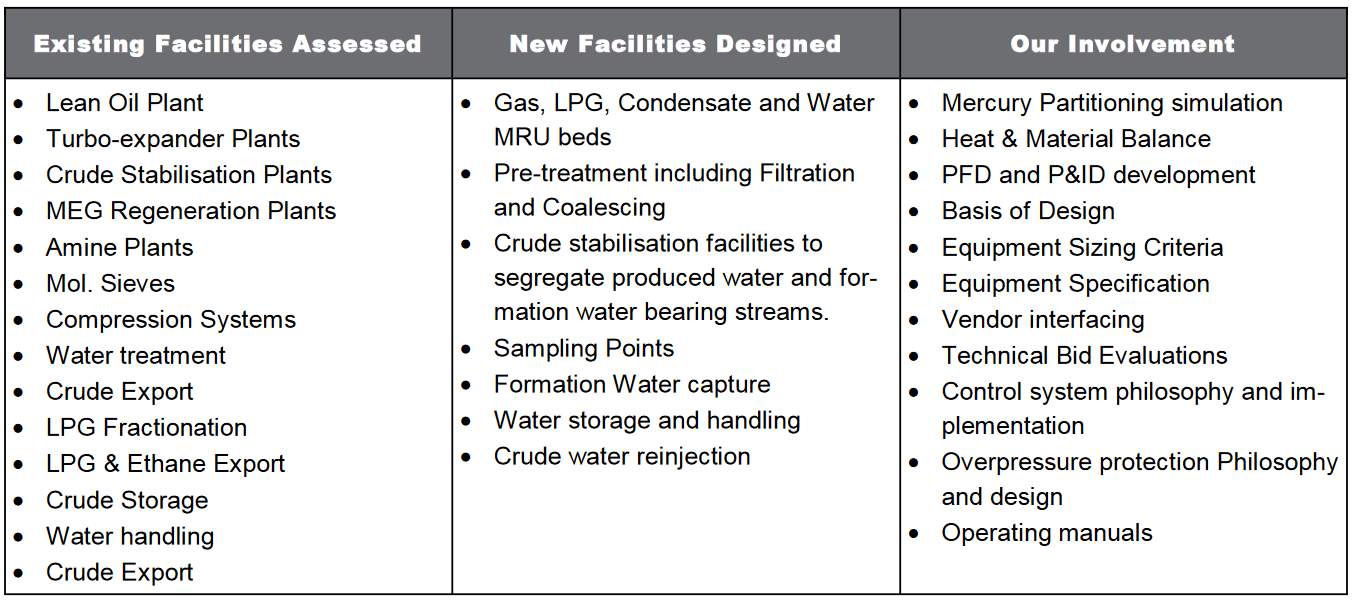

We have experience deriving mitigation concepts to address mercury loading in a range of facilities and can support clients to develop a concept through front-end, detailed engineering, construction, commissioning and start-up.

We do the following:

We work with experienced professionals to assist customers in the following areas:

Further information on these services can be provide upon request